Suppose you may have seen the latest document from Captain Tamburini et al on AA 587. I sympathize with their motives and goals, but sometimes am frustrated with how they treat some of the technical issues. In particular, they call for not using composites in primary aircraft structure, which really makes no sense and has no basis (in my humble opinion).

I’m forwarding this response to Tamburini to you as background. Just FYI, I had nothing to do with their report (at least that I am aware of).

-----Original

Message-----

From:

David

Maass

[mailto:david.p.maass@snet.net]

Sent: Wednesday, January 29,

2003 11:48

PM

To: 'Tambo700@aol.com'

Subject: RE: AA587 report

Captain Tamburini,

I read your report with great interest, and wish to commend you and your fellow authors for your continued efforts to understand what really happened to AA 587, and what ramifications that knowledge may have for safer operations in the future.

As you know, I have been vocal about some of the inaccurate and misleading information that has been provided to the media concerning composites and NDI. I wish to address those sections of your report specifically.

You suggest to NTSB and FAA that composites, due to their brittle nature, are not suited to primary structure. I believe it harms the credibility of your group to make statements such as this, because it exaggerates the issue and leads those who are experienced in the field to discount the qualifications of the group to reach valid conclusions, not just on this matter, but others as well.

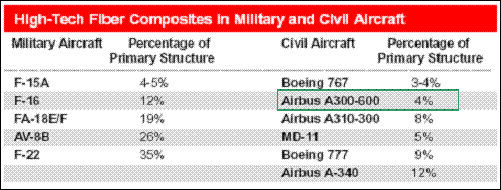

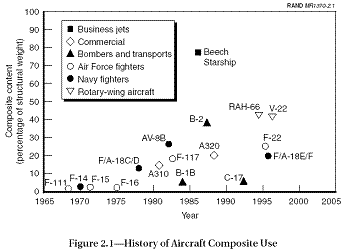

As you know and point out in the report, the percentage use of composites in both secondary and primary structure in both military and commercial aircraft continues to increase since first introduced in the 1970’s. The following charts provides a good historical sense:

There are very good reasons for this. Composites generally provide 15% to 25% weight saving when designed to meet identical safety criteria as their aluminum or titanium counterparts. This conclusion has been reached by many different companies, on many different aircraft, and by thousands of well qualified, safety conscious engineers. It is not a Boeing vs. Airbus issue, and no company (to my knowledge) uses materials or technologies which they consider unsafe or less safe.

It is not a black and white issue. Material selection, like most engineering choices, involves tradeoffs and comprises to achieve the “best” combination of characteristics. There are only two materials that offer the best of all words – Dreamium and Unobtanium. All other materials in the real world have some characteristics that are more attractive, and others that are considered drawbacks. The job of the materials and structures engineers is to select those that result in the optimum compromise, and to insure that reasonable and practical designs are created that are both functional and safe.

Certainly the composite materials used in commercial aircraft structure like Graphite/epoxy are much more brittle than traditional aluminum alloys. I also agree that in the general sense brittleness or lack of ductility is not desirable. However, this was well recognized long ago and is considered in establishing suitable design allowables (i.e. stress levels), safety factors, test procedures, etc. In other words, while brittleness is one of those characteristics of composites that has slowed down their introduction and acceptance (while engineers slowly and carefully learned to design with them), it is not a “we shall never use the stuff” situation.

Let me pose an analogy. The very high strength steels used in landing gears are also considerably more brittle than the aluminum alloys used in wing skins. However, when considering all the factors, landing gears are made from these materials because they provide the best combination of characteristics for that application. It is possible to design a landing gear from aluminum, but it would result in one that is not only heavier than a steel gear, but also far more bulky and difficult to package into the wings and fuselage. Having looked at all the alternatives, very high heat treat (i.e. more brittle) steel is widely used because it offers the “best” compromise when all things are considered, despite the fact that these alloys are brittle.

Make a long story shorter, while I respect your right to express your opinions, you may be fighting a losing battle (on composites) for no reason. Composite primary structure can be and has been safely fielded, and that is not the issue in AA 587 (in my opinion). To suggest otherwise weakens your entire case (in my opinion).

With respect to NDI, I and most other composite folks would agree that the 5 year visual observation regime is, as one executive suggested to me recently, “laughable at best and dangerous at worst.” This guy has been involved with composites in primary structure of front line military aircraft going back to the mid 1970’s (which are still safely in service, by the way). I have tried hard to enlist the support of others in my field to get involved in this issue, and have had limited success for a variety of reasons.

The good news about AA587 and this issue is that it has raised the profile of the importance of NDI, at least for a while. I can also say, based on specific knowledge, that some of the cognizant FAA technical folks realize they goofed initially, regardless of what the party line is, and have taken some tentative and reasonable steps to insure that safer practices are used going forward.

The bad news is that the spotlight has shifted away from composites and NDI as the primary causal factor (I say bad only in that people no longer think NDI is an important issue). This has allowed past errors or questionable judgment to go unreported or unnoticed except by those, like your group, who pay attention. It’s no longer a headline, and despite repeated efforts, I have only been able to generate a small amount of interest either in the engineering community or the aviation media. In fact, the FAA has cleverly and successfully avoided having to explain publicly why it has effectively done a 180 on NDI, so no one other than FAA really knows about it. I’ve tried to get half a dozen good journalists to probe this issue, without success.

As a result, what I fear is the old adage that those who fail to learn the mistakes of history are bound to repeat them.

Best of luck in your continuing efforts.

Dave Maass

-----Original

Message-----

From:

Tambo700@aol.com [mailto:Tambo700@aol.com]

Sent: Wednesday, January 29,

2003 5:06

PM

To: jhwill@mit.edu; Andrewweir1@aol.com;

david.p.maass@SNET.Net; safety@iasa-intl.com

Subject: AA587 report

Gentlemen,

This is our latest

report to the NTSB/FAA. As usual, we would like to thank all of you for

your direct -- and indirect --

contributions.

Regards,

Bob

Tamburini

Captain

American Airlines