|

Page One |

The Space Shuttle gets quality maintenance inspection and refurbishment in between its irregular sorties, however the average airliner gets regularly replenished and repaired only. Every five years or so an airliner will go in for a major service and in between those it will have lesser servicings, consisting of inspection for corrosion, obvious damage and implementation of any pending Service Bulletins or Airworthiness Directives - as well as elective upgrades (new in-flight entertainment systems). Any greater degree of servicing is impossible because an airliner only earns its keep by minimizing its down-time. That's called utilization. Lost up-time, rather than the cost of pristine maintenance, is the reason why undetected flaws and chronic degradation can be expected on an airliner - but not on a Shuttle.

That leads to the difference between the Space shuttle's pristine wiring and that to be found on the older (and the elderly) airliners. That's the risk you run - and the astronauts don't.

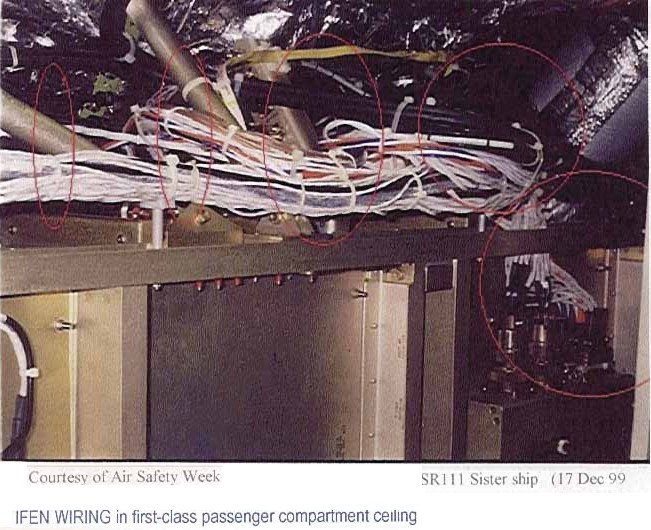

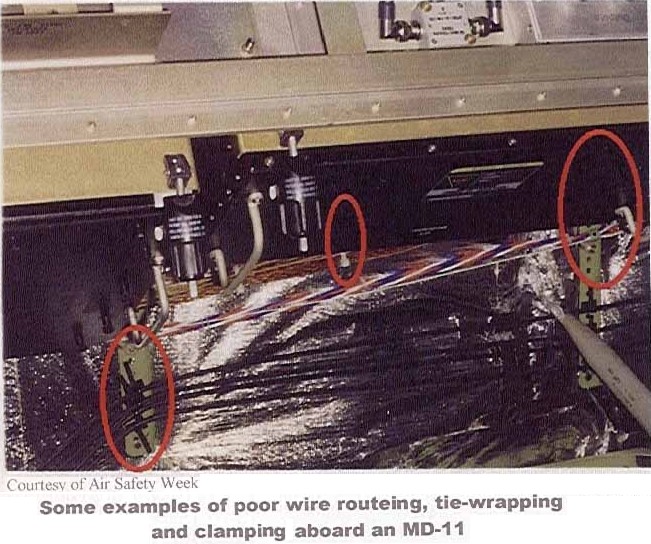

| This might pass muster as spaghetti in an Italian restaurant - but just keep in mind that you don't need much to start an electrical fire. Too tight a bend radius, chafe induced by a mix of soft and hard wiring insulation types, a metal corner, the continual high frequency vibration of flight, the flexing of the fuselage under dynamic and heat variation stresses. Aromatic polyimides (Kapton types) are unique in that they can both wet arc and dry arc. Drip water on an elderly length of powered Kapton - and get your hair singed, as it responds explosively. Older Kapton suffers from top-coat flaking and then starts "ticking" away in "ticking fault" mode as current leaks to adjacent conductors courtesy of microscopic cracks in the wire's insulation. |

|

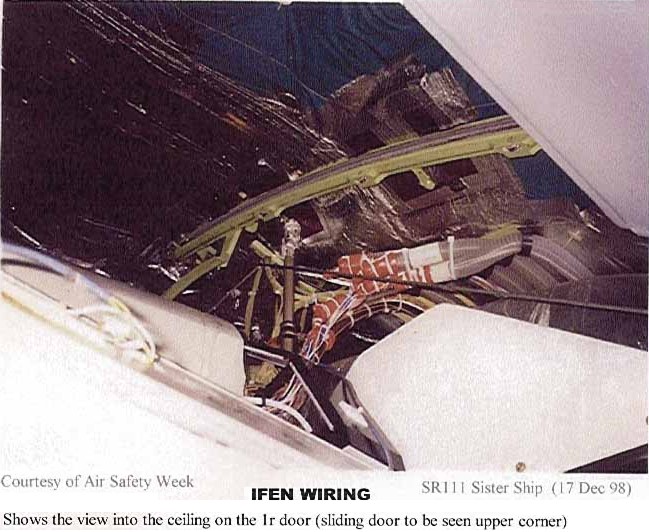

Note the grey thermal/acoustic blankets. They are flammable

when new and get worse with the years (as they pick up contaminants). They

are known to have spread electrical fires in many aircraft - both before and

after Swissair Flight 111 on 2 Sep 98. They have been condemned to "be removed within five years." In this area of the cabin ceiling of an SR-111 sister-ship, wiring faults, chafing and arcing were found (possibly related to the door's run along the rail-tracks seen here). |

| Because of the many hundreds of kilometres of wiring on an aircraft you only have to have one significant flaw develop over time in order to have significant grief. Because the wiring is bundled together in wiring bundles and fed through small holes in bulkheads there are many many areas (sight unseen) where problems can develop. Why do they develop? Unlike the space shuttle which flies under heavy vibration for only a short period, airliners always have the high frequency vibration of flight to contend with. Over time this can have a sandpapering effect between hard and soft wiring insulation (such as between the introduced Tefzel and existing Kapton on Swissair Flight 111's In-flight Entertainment System). |

|

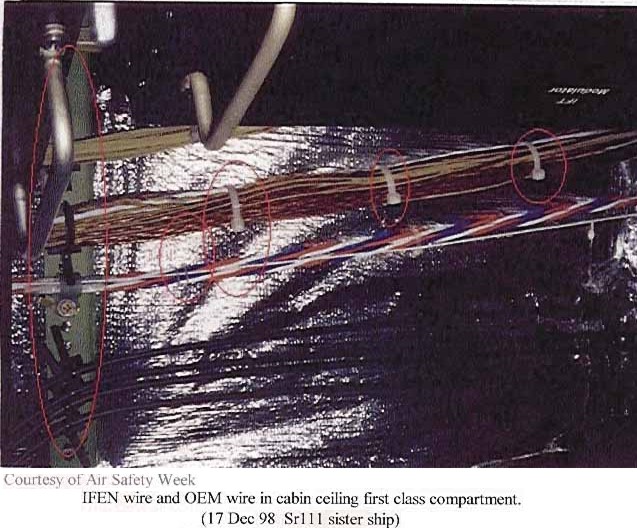

An example mix of hard and soft wiring in the

ceiling. The shiny background is the metallized mylar (flammable and

condemned to be removed and replaced by another type of

thermal/acoustic blanket within five years). Industry thinking now is

that wire-bundles should not approach each other any closer than two

(2) inches. That is to preclude the possibility of arc-tracking up and

down one wiring bundle taking out the adjacent wire-bundle. Could you imagine the pilot's consternation up front as many disassociated systems die one after the other? Maybe back in the cabin there won't be much more than a wisp of smoke (as it all happens behind the cabin lining). It's the subsequent fire, promulgated by the air-currents and flammable mylar beneath the cabin lining, that would then go on to do the real damage. That's right, up there where the oxygen generators and/or oxygen tubing is located. |

Here follows a number of pages demonstrating what can happen to wiring when fair wear and tear gives way to chafing, ticking faults, arcing, fire and system failures. But all you will see are the burnt wires, not the possible end-results of systems failure, general outbreaks of fire, toxic gas, crew and passenger incapacitation etc.