The IASA

Chairman’s NASA

Experience

(Mrs. Lyn S. Romano

“Meets” Discovery – “Up Close & Personal”)

|

Place: KSC

(Kennedy Space

Center – Florida)

Date: 29

May 2002

Time: 10:43AM (Security badge issued)

|

|

|

|

|

Once you’ve read through my Report, I hope that you will hit this

link and look over some of the Shuttle Photos

|

|

|

You will then be in good shape to

make an informed “comparison” with some airliner wiring photos (at this link)

|

|

"In the press grandstand where I watched Discovery rise against the cloudless sky, the media hit the abort button on

cynicism. The Earth shook to the sounds of man, three

miles away. The candle lit. . . only someone

stripped of awe can leave a launch untouched.

— Jonathan Alter, 'Newsweek' magazine, 9 November, 1998

|

Genesis

I was recently granted the

honor of being invited to Kennedy Space

Center (hereinafter referred to as

KSC). The purpose of this invitation was to enable me the

opportunity of inspecting the wiring of the

space shuttle – Discovery – during “her” 20-24 month maintenance mode, and it

was an experience I shall never forget, for many reasons.

Greeted at Orlando

Airport by Ms. Kim Knight (KSC), I

knew immediately I was a welcomed guest.

As we headed for KSC I had no real idea of what to expect, but Kim could

not have made me feel more welcomed and relaxed – something I desperately

needed as I tried to make sense out of how I “got here” in the

first place.

I cleared the first, of

many, security checkpoints at 10:43AM.

We navigated our way through the corridors of the

NASA building, stepped onto the elevator and

rode it up to the 5th floor for my

meeting with the gentlemen that I would spend the

next 6 hours with.

I had spoken to and corresponded with one of the

gentlemen I would be meeting with - on many occasions prior to my visit. He is

with Johnson Space

Center, located in Houston,

Texas (hereinafter referred to as JSC) and

he is responsible for the shuttle fleet’s

safety. I should mention here I had never had the

opportunity, before 29 May 2002,

to meet him personally. The other gentleman I

would be meeting, for the first time without the

benefit of previous contact of any kind, heads up the

electrical engineering group at KSC.

As I sat across the table

from these two men, with the

“over the top” expertise they

possess in their respective fields, I was

struck by the fact it took only minutes of

discussion for them to realize I possessed

more than a basic understanding of the wiring

issues confronting the world of commercial

aviation. It did not take long for them to

learn of my eagerness to be educated about the

same wiring concerns confronting them in their

realm. Not once did I feel they were

“assigned” to pay me lip service of any kind, to “get this over with” or “Give the

lady the fluff ‘n’ stuff treatment”. For that,

I am eternally grateful. I have had more than my share of that “fluff ‘n’ stuff

treatment” during the course of too many

meetings over the past three and a quarter

years.

The “plan” was to have lunch before heading over to inspect the

wiring of Discovery, but I suggested we skip lunch and head straight over to the

Orbiter Processing

Center, because I was more than

anxious to “get right to it”. Thankfully, they

agreed without hesitation, and we were off.

After clearing security, once again, I was led into the

building that houses – Discovery – during “her” down-time.

As I stood beneath this magnificent “bird”, staring up at the

thermal tiles that protect the

shuttle from burning up on re-entry, I could barely breathe,

let alone sort out the conflicting emotions of

what brought me here.

It did not take me too long to realize that it was the

229 souls who perished aboard swissair Flight 111 on 2 September 1998, when that American manufactured

aircraft, (an MD-11) plummeted into the cold,

dark waters in close proximity to peggy’s cove, in Nova

Scotia, Canada

brought me here. Each and every one of those human beings, who in my estimation

did not have to perish that night in such a horrific way, are/were exactly what

brought me here.

*To date, the final report

surrounding the crash of swissair Flight 111

has not been released by the Canadian

Transportation Safety Board (hereinafter referred to as the

CTSB). However, much of the CTSB’s

investigation has focused on:

1.

The wiring of that aircraft (from type to installation)

2.

The In-Flight Entertainment System’s wiring and

installation

3.

Inadequate wire testing standards

4.

Inadequate material flammability standards

….as well as a myriad of other

aviation safety issues not in effect at the

time of the swissair crash, which could have

possibly prevented this particular aviation disaster from occurring. Due to these

facts, I cannot accept (as many in aviation circles seem to have), that the

crash of swissair 111 was in fact, just an accident*.

Differences - and No Indifference

This

clarified for me just how I ended up at NASA. I suppose I was meant to witness

first hand how NASA is addressing the wiring

concerns they have been confronted with, in

order to see for myself what they had been

telling me for several months, since my initial communication with the

gentleman at JSC. What was he telling

me? Specifically, NASA is most concerned with providing the

human beings that board their shuttles the

highest level of safety humanly possible. The safety they

deserve. We all know disasters happen, BUT, when there

are means to ensure the safest possible

environment, either in the

commercial aircraft realm or the space shuttle

realm, they need to be aggressively

undertaken, something NASA has chosen to act on and not just talk about.

Talking about it, rather then

acting aggressively seems to be the course the

commercial realm of aviation has chosen instead.

This

clarified for me just how I ended up at NASA. I suppose I was meant to witness

first hand how NASA is addressing the wiring

concerns they have been confronted with, in

order to see for myself what they had been

telling me for several months, since my initial communication with the

gentleman at JSC. What was he telling

me? Specifically, NASA is most concerned with providing the

human beings that board their shuttles the

highest level of safety humanly possible. The safety they

deserve. We all know disasters happen, BUT, when there

are means to ensure the safest possible

environment, either in the

commercial aircraft realm or the space shuttle

realm, they need to be aggressively

undertaken, something NASA has chosen to act on and not just talk about.

Talking about it, rather then

acting aggressively seems to be the course the

commercial realm of aviation has chosen instead.

To give you a “snapshot” of Discovery, here are “her”

statistics:

WING SPAN: 23.79

meters

LENGTH: 37.24

meters

HEIGHT: 17.27

meters

PAYLOAD BAY: 18.3

meters x 4.6 meters

PAYLOAD WEIGHT (launch max): 24,948 kilograms

MAIN ENGINE (each)

THRUST @ 100% THROTTLE

SETTING:

SEA LEVEL: 1,670

kilonewtons

VACUUM: 2,100

kilonewtons

EXTERNAL TANK (ET)

LENGTH: 47

meters

DIAMETER: 8.4

meters

GROSS WEIGHT (full) 750,980

kilograms

SOLID ROCKET BOOSTER (SRB – Each):

LENGTH: 45.46

meters

DIAMETER: 3.7

meters

THRUST @ LIFTOFF: 14,685

kilonewtons

GROSS WEIGHT (approx): 589,670

kilograms

Having taken a long look at the

thermal tiles from beneath the

shuttle, it was time to walk up the steps of the

scaffolding that surrounded Discovery, to clear another

security checkpoint, enter the air wash

chamber, then don our “Bunny Suits” (A “Bunny

Suit” is what I am wearing in the photos that

accompany this report) before being granted access to crawl into the

shuttle Discovery. All those tasks now complete – I find myself standing in the

Midbody portion of the shuttle. I cannot

possibly put into words the feelings

associated with that moment. Therefore, I will report only on what I saw – and

not what I was feeling at that time.

To my right, upon entering the

shuttle is the crew’s bathroom. Just beyond

that, still on my right, is an opening revealing the

Payload Bay.

This cavernous, empty, bay area is beyond my scope. What was it they

told me? How many school buses fit into this area? That’s just to give you an

idea of the enormity of “space” I am referring

to when confronted with this portion of the

space shuttle. Once I was able to pull myself away from the

Payload Bay

area, the electrical engineer lifted a floor

panel in the Midbody section to reveal the

work they are accomplishing in their

ongoing modifications to the wiring contained

throughout this ship. “The Belly” is how I would refer to this portion of the

shuttle.

NASA Refuses to

“wear a Wire”

Some of the configuration

changes being tended to are in the area of the

Midbody Crossover Bracket Redesign. Wire trays have been redesigned to

“eliminate interference that has existed between the

Orbiter Midbody Centerline Purge Duct and the

wire  harnesses

contained in the mainframe crossover trays”.

This is being accomplished by the use of

tie-wraps and harness routing as well as a Teflon wrap

to protect the harnesses in contact areas.

Wire bundles will rest on vulcanized rubber, providing another

measure of safety.

harnesses

contained in the mainframe crossover trays”.

This is being accomplished by the use of

tie-wraps and harness routing as well as a Teflon wrap

to protect the harnesses in contact areas.

Wire bundles will rest on vulcanized rubber, providing another

measure of safety.

The fleet wiring investigation (which NASA takes very

seriously) “gave birth” to the redesign of these

wire trays. They specifically curve around the

Purge Duct and allow the harnesses to be

mounted on the far side of the

tray. This is being accomplished not only as an enhanced safety measure, but

also to accommodate future growth.

As I look around the

Midbody section, I can see how much attention is being paid to ensure the

bend radius of the wiring is smooth, as it

“snakes” its way up, around and through the

craft. Adequate wire separation is also apparent. This being a very “hot topic”

item of discussion in the commercial aviation

realm recently, I was quite impressed to see this vital safety enhancement

already being tended to by NASA.

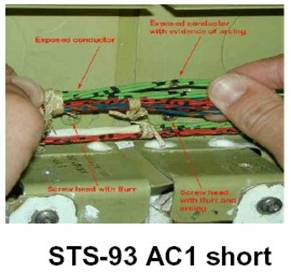

The pristine conditions stunned me. Considering Discovery is

in the heavy maintenance mode, I would have

expected far less – I was more than pleasantly surprised to learn quite the

opposite. Although I have never been personally granted a physical, visual

inspection of a commercial or cargo aircraft (and not for a lack of trying – I

assure you) I have seen many photographs and have been delivered many written

reports by experts in the aviation safety

field who have. Those photos and reports would shock the

average airline passenger. Comparing the

shuttle in a heavy maintenance mode, to the

reports and photographs I have seen detailing commercial aircraft (and I am not

referring to a heavy maintenance mode in the

commercial realm here, but those aircraft allowed to be transporting passengers

on a daily basis) all I can report is that there

is NO comparison.

There was not a speck of dust, lint, metal shavings or build

up of “gunk” on any of the wire bundles I saw

– on either the

very visible bundles, or the ones within the

“Belly” of the shuttle, which is considered a

less than accessible area. Therefore, the

condition of the wiring I was granted to

inspect on Discovery, even during this drastic maintenance mode, reassured me

that the visual inspections NASA wire experts

carry out are far more realistic and effective than any visual inspection that

is carried out on a commercial airliner. I must reiterate at this point, I have

never been granted access to a commercial/cargo aircraft during the

same type of maintenance mode, and therefore,

I can only base my findings on what I have been delivered by way of photographs

and reports that have been directed my way by the

experts in the commercial aircraft/aviation

safety realm.

Having completed my inspection of the

“Belly” and Midbody portions of Discovery, we head up the

stairs to the Flight Deck. It was an awe

inspiring experience for me to be standing in the

spot where Discovery will, after having completed “her” 20-24 month down time,

be once again navigated through space by one of our incredibly brave astronaut

teams. Considering that experience would be far too difficult for me to put

into words, I will continue with reporting what I saw, rather

than what I felt.

The close quarters were mind boggling, bordering on claustrophobic.

Looking up and seeing the “portals” through

which the Discovery crew will once again “slip

out” into space to accomplish whatever task is assigned, was awesome. A portion

of the ship’s wiring here is of Russian

origin/design. Any work needing to be attended to on this particular wiring is

not undertaken at NASA, but in Russia.

The bundles run through the

shuttle into pressurized zones – another vital

area NASA tends to in “over the top” detail.

I cannot tell you how long (in minutes or hours) I spent on

Discovery – Discovering for myself up close and personal, how everything I had

heard from NASA before arriving for this inspection had just been confirmed.

NASA takes the wiring issues that confront their

particular realm of aviation very seriously and I am convinced they

are doing everything humanly possibly to ensure a safe environment for the

human beings they launch into space. Not only the

Americans they send “up there”,

but all the human beings in “their

charge”. I find it very unfortunate not to be able to say the

same for the commercial side of aviation –

from the manufacturers to the

airlines to the regulators that “cry” safety

first and foremost.

No Cost/Benefit Sums Added Here

Astronauts and the Space

Station (ISS) crews who board our shuttles for

destinations we will most likely only be able to absorb through our

imaginations, are not referred to as “occupied  seats”.

There is no price tag on their life and Cost

Benefit Analysis (hereinafter referred to as CBA) has no place. Passengers

boarding a commercial airliner are referred to as PAX or “occupied seats”. The

price tag for a human life on board a commercial airliner is $2.7 million

dollars, and a CBA approach to civil aviation disasters is considered an

acceptable/necessary “tool”. To clarify this just a bit, for those unaware, CBA

is the statistical methodology utilized to

determine which aviation safety measures are cost effective to implement and

which are not. Basically, if $2.7 million X the

number of human beings killed in an aviation disaster

is determined to be less expensive then the

cost of implementing a specific safety enhancement – it is not deemed cost

effective and therefore is not considered

practical. The bottom line is then that the

measure does not get implemented. To summarize, it’s far less expensive for the

airlines or manufacturers to pay settlements AFTER a disaster, than to attempt

a real “fix” BEFORE the disaster. In aviation

circles this mindset is referred to as a Tombstone Mentality. Reactive instead of Proactive. Who is in charge of our

safety? The gentlemen I spent many hours with at NASA weren’t aware of this CBA

methodology, but I can assure you, they are

now – were you aware of this? You do have the

right to know, therefore, I felt compelled to

include this explanation in my report at this time.

seats”.

There is no price tag on their life and Cost

Benefit Analysis (hereinafter referred to as CBA) has no place. Passengers

boarding a commercial airliner are referred to as PAX or “occupied seats”. The

price tag for a human life on board a commercial airliner is $2.7 million

dollars, and a CBA approach to civil aviation disasters is considered an

acceptable/necessary “tool”. To clarify this just a bit, for those unaware, CBA

is the statistical methodology utilized to

determine which aviation safety measures are cost effective to implement and

which are not. Basically, if $2.7 million X the

number of human beings killed in an aviation disaster

is determined to be less expensive then the

cost of implementing a specific safety enhancement – it is not deemed cost

effective and therefore is not considered

practical. The bottom line is then that the

measure does not get implemented. To summarize, it’s far less expensive for the

airlines or manufacturers to pay settlements AFTER a disaster, than to attempt

a real “fix” BEFORE the disaster. In aviation

circles this mindset is referred to as a Tombstone Mentality. Reactive instead of Proactive. Who is in charge of our

safety? The gentlemen I spent many hours with at NASA weren’t aware of this CBA

methodology, but I can assure you, they are

now – were you aware of this? You do have the

right to know, therefore, I felt compelled to

include this explanation in my report at this time.

It was now time to crawl out of the

shuttle and remove my “Bunny Suit” in order to inspect Discovery from the

outside, before heading down to the “tool

room”. “She” is as magnificent from the

outside, as “she” is on the inside.

Strict precautions have been put into place to ensure the

proper tool is used for the specific job

requiring its use. They are all precisely calibrated, all sealed in plastic

with detailed written instructions for the

tool’s specific use. If a maintenance engineer is handed a sealed plastic “tool

bag” that appears to have already been opened, he does not accept it. There is

also a time limit as to how long the tool can

remain out and they must be returned by the

specified time. No tool is allowed to dangle from a tool belt. This precaution

has been implemented to ensure (as much as possible) that no accidental damage

to the wiring takes place while work continues

in those specific areas of the shuttle. While

speaking with the gentleman in charge, I could

not help but think about the lives lost in the

Alaska Airlines Flight 261 disaster, apparently due to shoddy maintenance and

tool calibration practices for which the

Federal Aviation Administration (hereinafter referred to as faa) were fully

aware. I wondered how much of an impact NASA’s practices would have had in

avoiding that particular disaster. Shades of the

earlier Valujet disaster, Alaska Airlines had already been in court for several

years, over the faa’s

“complaints” regarding what they believed to

be shoddy maintenance practices, so they were

fully cognizant of the difficulties the

airline seemed to be facing, tending to this most vital area of aviation

safety.

Once my conversation/education was complete with the

gentleman in charge of the “tool room”, we

made our way over to the wiring training

facility and I met with the man in charge of

training any and all who will come in contact with the

shuttle’s wiring.

In NASA a “Standard” is

a Criterion of Excellence not a Requirement for Conformity

Physical examples of wiring are displayed here to enhance

understanding about what is and is not acceptable when installing or

maintaining the wiring on the

shuttles. Also very useful for those who visually inspect the wiring. I

“flipped through” training manuals used and having already personally viewed the

Orbiter Wiring Training Video myself (a must for anyone at NASA who will be

working on any shuttle wiring) I was once again impressed at the

attention NASA has devoted to the wire systems

on the shuttle fleet.

The culmination of my “field inspections” could not have

been more profound. Upon completion of my visit to the

wire training facility, I was taken over to the

launch pad where Endeavor “sat”, encased in scaffolding awaiting

what was to be “her” launch the following day

(scheduled for 30 May 2002).

Once again I found myself not believing I was actually here.

I was educated about how the shuttle first

arrives at the pad – to when “she” launches.

The following day – Thursday, 30 May

2002, Endeavor was to launch (on “her” way to the

International Space Station) and I had been invited to witness this incredible

moment from Banana Creek, approximately four and a half miles away from the

exact site I was now being granted an up close and personal ‘visit’. The name

of the mission Endeavor was set to embark upon

the next day:

STS 111

The timing of my invitation to inspect the

wiring on Discovery, and to witness this particular launch was an incredible

coincidence that even those at NASA I mentioned it to were

stunned to learn of. swissair Flight 111, the

flight my husband Ray Romano took on 2

September 1998 – together with 228

other unsuspecting human beings – never made

it to their scheduled destination. Endeavor’s

scheduled launch – mission STS 111 – was ready to go the

very next day. Would I be?

Returning to the offices at

NASA – where I began the day approximately

five hours earlier, the three of us had the

opportunity to wrap up. It also gave me the

ability to deliver a summary (of sorts) as to what I will do with the

education and photos I had just been privileged to receive. The gratitude I

feel for the generosity of time and expertise

granted me during this visit by these two men

(not to mention all those involved in making this experience possible for me -

both at JSC as well as KSC) is something I will never be able to appropriately

express.

I did, however, have the

ability to explain to each of them that I

would be heading down to Washington DC the 12th

and 13th of this month (meetings were already scheduled prior to my

NASA visit) to meet with Mr. Sam Whitehorn (Senator Hollings chief of Staff)

and Mr. Nicholas Sabatini (recently appointed to the

position of Associate Administrator for Aircraft Certification at the

faa – stepping into the position vacated in the

Fall of 2001 by tom mcsweeny who left for a position with boeing) to deliver the

details of my inspection of the wiring on the

shuttle Discovery. I also told them I would

bring with me the photos depicting NASA’s

attention to wire safety, together with my

report.

It would be my fondest wish come true (in the

“life” I have been left with since the crash

of swissair Flight 111) if upon receipt of these

two items, the faa, as well as those in the

position to actually get aggressive attention focused on this most vital

aviation safety concern could be accomplished. If not these

findings, I certainly do not know what it will take to get the

attention that is so vital, but I have no intention of stopping there,

if I am still met with deaf ears. It is my firm belief that the

commercial arm of aviation should and must follow NASA’s lead…. for true

aviation safety’s sake.

The United States

government delivered $15 billion to the

airlines, following the atrocities that took

place on U.S.

soil 11 September 2001.

This was done to “bail out” the airlines when they

were faced with their financial slump post

911. Considering the age of many of the

commercial aircraft in the U.S. airline fleet,

and the fact that a major percentage of that

fleet contains not only dangerous wiring, but more than apparent lack of

attention to proper maintenance procedures (as compared to the

United States – NASA shuttle fleet), I feel compelled to take what I have

learned during my recent visit to Washington DC.

After seeing the work being

accomplished at NASA in respect of the wiring

issues confronting them, and considering the

budget constraints they have to work within in

order to tend to these necessary upgrades and

modifications, I cannot help but wonder where the

$15 billion would have accomplished far more. NASA, or

civil aviation? If NASA can take the

aggressive measures they are concerning the

wiring issue, the action I have now seen for

myself, what does it take to get the same response

time/attention in the civil aviation world?

More people killed? That would certainly “up” the

costings in the Cost

Benefit Analysis mindset, but I daresay that is not a socially acceptable

answer.

Is it the United

States aviation industry, or those who

regulate it, intention to keep aging aircraft flying at any cost? Without

immediate and long overdue aggressive action to finally “make right” what has

long since been a “discussion topic” while more and more human beings are

needlessly killed? Will they be able to

continue to use the Cost Benefit Analysis

methodology when more and more of these aging

aircraft fall from the sky? No matter whether

it be on United States

soil or elsewhere around the world?

Considering the airline’s profit margins are

apparently less than acceptable at this time, will any of that $15 billion

‘grant’ delivered by the United States

government to the airline industry be put

towards the many safety issues that have been

allowed to fall by the wayside for far too

long already? Have the all too deadly wiring

issues that have been known about for at least 30 years been placed on the

“back burner” as they have been for too long,

now that the 911 atrocities make it easier for

them to disappear from the

‘agenda’? Will the United States be able to

remain the aviation “Super Power” it

(outwardly) has been, because it is simply receiving an “injection” of cash to

keep the aging aircraft fleet in the

sky – at the risk of human life? How many

human beings will it take to finally accomplish what should have been

accomplished by those “powers that be”, to finally have them

be able to state – truthfully – “safety first”? Thankfully, NASA seems to have

figured out the answers to most of these

questions, if not all of them.

The NASA Wakeup Call

NASA grounded their shuttle

fleet for six months in 1999, in order to inspect the

wiring after learning of unacceptable  conditions

during one of their missions. I suppose they

were able to do that because they have the

motivation to do so, for several reasons.

conditions

during one of their missions. I suppose they

were able to do that because they have the

motivation to do so, for several reasons.

They cannot risk the loss

of a shuttle, not only because the space

program (their “industry” if you will) would

suffer drastically, but there would also be

(most assuredly) loss of human life. A fact that always enters into their

safety discussions, at least the discussions I

have had with them. NASA’s motivation is not

profit – not in dollars and cents. I firmly believe NASA could find more than

appropriate ways to utilize the same

“injection of cash” the airlines were granted

post 911.

If the regulators,

manufacturers and airlines in the United

States (and around the

world for that matter) are as concerned with “safety first” as they

profess to be, than why has the wiring issue

been allowed to confront them to this very

day? Will the U.S.

be able to maintain their (outward)

superiority in the commercial aviation arena,

when more and more of those U.S.

manufactured aircraft fall out of the skies?

No matter where they happen to fall? Will the

regulators continue to allow these conditions

to flourish as they apparently have in the

past? Will they continue to pick and choose the

vital safety enhancements, utilizing the Cost

Benefit Analysis formula?

$2.7 million X the number

of human beings killed in an aviation disaster as their

bottom line?

I realize how unrealistic it is to expect a rewiring program

be put into effect for the aging aircraft

fleet in this country, or any county around the

world. Most especially post 11

September 2001. Therefore, what I hope to accomplish as I take the

information I was granted during my trip to NASA is simply this:

If NASA has the ability to

provide their shuttle crew the

level of safety they are aggressively seeking

– without a $15 billion “injection of cash” to make that happen - than

certainly the commercial realm of aviation,

from the manufacturer to the

regulators, to the airlines need to do the

same for the human lives they

have been given the responsibility to protect,

as much as humanly possible. After all, they

keep telling us how safety is their primary concern,

right? Now would be the time to finally show

us they mean what they

say. As NASA has shown me, not in words, but by their

aggressive action to do whatever’s humanly possible to ensure the

safety their crew so rightfully deserves. Are the

individual’s lives that board the shuttle

worth more than yours or mine?

One life is priceless, as I have said from 3 September 1998 to this day – and I

will continue to say that, because it happens to be a fact. I do not need to

rely upon Cost Benefit Analysis for my “findings”, as some in the

aviation world apparently do. NASA has figured that out as well. When will the

human beings that step onto a commercial aircraft be granted that same

assurance? If rewiring of aircraft in the

commercial realm is not realistic, then

shouldn’t the regulators compel the

airlines at the very least - - to deliver the

same pristine and meticulously maintained wiring in their

fleets as NASA has accomplished for their

shuttle fleet?

I would like to take this opportunity to thank each and

every individual at both JSC and KSC who went “above and beyond” what I could

have ever hoped for in order to make this trip not only possible, but one I

shall never forget.

It was my decision to withhold their

names from my report. I realize there might be

many aviation safety minded individuals – upon reading this report – who would

inundate their phone, fax and email lines –

with only good intentions of course. Considering what the

gentlemen and ladies employed by NASA (both at JSC and KSC) tend to on a day to

day basis, I felt it appropriate not to deliver any of their

names, in order to do my part in helping them

accomplish the continuing aggressive measures they

have undertaken towards real wiring safety.

God’s Speed,

Lyn S. Romano

Chairman

IASA/US (International

Aviation Safety Association)

Wife of Raymond M. Romano

Passenger on swissair Flight 111

Seat 9F

|

"Discovery is

seeing what everyone else has seen and thinking what no one else has

thought."

Albert Szent-Gyorgi

|

A Reminder to click this banner

for the IASA Visit Shuttle Photos

This

clarified for me just how I ended up at NASA. I suppose I was meant to witness

first hand how NASA is addressing

This

clarified for me just how I ended up at NASA. I suppose I was meant to witness

first hand how NASA is addressing  harnesses

contained in

harnesses

contained in

seats”.

There is no price tag on

seats”.

There is no price tag on

conditions

during one of

conditions

during one of